1. Sand paper the PCB with abrasive paper (P400)

2. Prepare the OHP with the circuit printed on it.

3. Place the ready OHP onto the PCB.

4. Ironing the PCB with the OHP on it.

5. Wait until the ironed PCB has cool down. Then take the OHP off from the PCB slowly.

6. The ready PCB with circuit on it

7. Prepare the Ferrous acid and soak the ready PCB in it.

8. Soak the PCB for 10-15 minutes to remove the unwanted copper so that only the circuit will remain on the PCB.

9. Etching the PCB using sand paper.

10. The ready PCB

11. The process of assembling components on the PCB.

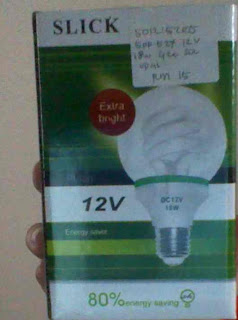

Since we could not find any electronic or electrical store that selling the 12V fluorescent lamp, we replaced them with this bulb.

We could not find the battery charger as specified on the magazine which is MB-3526 12V 1A in the marker. So we use the Autobike Battery Charger to charge the SLA battery so that the battery can be used to run a test on our project.

The controller was connected to the battery

We run a test on our project.

Problem

We have run a test to see whether the circuit of the controller for the emergency light is working or not. The circuit seems to be working properly. The only problem we have now is we do not know how we can find the right charger. The charger for this circuit are supposed to be MB-3526 Battery Charger 12V 1A. We went to many electronic store and ask the person in charge there for this type of charger but they don't have SLA battery charger 12V with 1A. What they have is 12V 2A.

Conclusion.

The process of assembling the components is succeed. But we must find the right charger for our project or we have to do some add the value of the resistor near the main power to prevent the Mains Power LED indicator from burning due to over current passing through it